This article was first published in the Nov/Dec 2018 edition of inspire magazine.

The Internet of Everything. Artificial intelligence. Unmanned aerial vehicles. Technological changes to our world and workplace can be baffling, jargon heavy, and occasionally concerning, depending on the tone of their coverage. For public works and civil engineering professionals, they are reinventing how assets are designed, built and managed.

“Public works and asset intensive entities can use different technologies to achieve optimal performance, and there are myriad options in the market to help us with that objective”, Steve Verity, Strategic Asset Management Consultant at TechnologyOne, tells

inspire.“For public works, particularly in local government, doing more with less is the norm, and any viable technology out there that is going to help them get an advantage is worth exploring.”

A technology that continues to optimise all stages of an asset’s life cycle is building information modelling.

“The continued advancement in data-rich 3D building information models (BIM) is allowing construction teams to visualise the project, while identifying and resolving conflicts prior to beginning work on site,” Stephen Grigg, Arup Digital Engineering Leader Queensland, tells inspire.

It is used for designing built assets (enabling this in increasingly impressive levels of detail), as well as cloud collaboration on shared models across disciplines throughout projects and in information maintenance through an asset’s life.

The Nepean River pedestrian bridge – including a great deal of hidden features – was designed “to the nth degree” in Revit, Joe Turner, Principal Bridge Engineer at BG&E, tells

inspire.“It’s such an aesthetically different structure, and having that 3D model just allows you to visualise and make sure things fit,” he says.

“The maintenance team in the future is going to be able to access certain elements for inspection and repainting. It allows you to tick so many boxes from not just buildability, but maintainability and safety.”

GIS (geographic information system) data is another source of vital information. GIS is used to map things, quantities and densities, as well as describe features and map change over time within an area of interest.

GIS information is two-dimensional, unlike BIM data, and describes geographic rather than structural detail. However, as engineering.com noted in July, “the last few years have seen a steady increase in the number of professionals looking to combine them.” This is arguably an area to watch.

Drones, another industry trend in the last few years, are aiding in the collection of geographic data for the design stage of projects (and far beyond).

According to Verity, two newer developments are the use of drones for investigations and 3D printing for design communication. His current role involves assisting asset-intensive organisations to make evidence-based infrastructure investment decisions and communicate complex engineering outcomes to stakeholders.

“[3D printing] helps decision makers make a more informed decision about which option is more appropriate to meet community needs,” Verity explains.

A more automated construction site

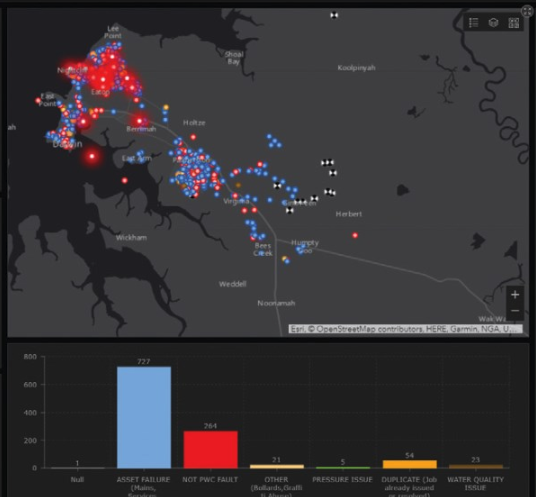

Esri Australia’s Operations Dashboard gives real-time situational awareness for PWC on leak status. Image supplied by Power and Water Corporation NT.

Esri Australia’s Operations Dashboard gives real-time situational awareness for PWC on leak status. Image supplied by Power and Water Corporation NT.

He adds that the trends of prefabrication and modular construction should continue. Companies such as Laing O’Rourke highlight this approach as a way to minimise project time, environmental impact and disruption to communities. This also reduces risk of interruption due to poor weather and operating conditions.

“If something can be prefabricated offsite and delivered to site at a lower cost – particularly in high density urban environments where building onsite is challenging and costly – then it’s going to be advantageous for everyone,” Verity says.

Modular construction, with as much built offsite as possible, can see jobs then speedily plugged together onsite. Laing O’Rourke calls this approach design for manufacture and assembly (DfMA) or ‘modular manufacturing’.

It may be further off in terms of maturity, but companies including Laing O’Rourke are looking to another technological concept from the manufacturing industry, 3D printing, to deliver improved productivity.

Developed in Australia by architect Dr James Gardiner, the robotic FreeFAB system lays down moulds, layer by layer, out of a reusable wax material. These have been used to create hundreds of precast concrete panels for the European Crossrail project, which The Economist reports was the first major construction project to use 3D printing.

More recently, Mx3D unveiled an intricate, 12-metre, 3D-printed metal footbridge in Amsterdam.

Overall, civil engineering projects are currently adopting a “more sophisticated way of working," according to Stephen Grigg, Arup Digital Engineering Leader Queensland.

“The industry is moving towards a more automated construction site with the use of unmanned aerial vehicles (UAVs or drones) and construction machinery utilising 3D machine guidance and positioning systems,” he tells

inspire.Cloud-based solutions for processing large amounts of data, such as point cloud survey scans and aerial imagery, are becoming more affordable and accessible. These, and trends such as the Internet of Things, are spreading throughout every industry and “will continue to shape and improve the built environment, having a lasting impact in society,” Grigg believes.

“In order to leverage the benefits of these technologies on projects, it is important to plan the full life-cycle works at its inception. Collaborating with industry leaders can greatly benefit organisations, especially during early adoption.”

A clearer view

Moore Park, Sydney, night roadworks. Sydney Water is collaborating with other agencies through the SmarterWX platform to minimise disruption on public works. Image supplied by Sydney Water.

Moore Park, Sydney, night roadworks. Sydney Water is collaborating with other agencies through the SmarterWX platform to minimise disruption on public works. Image supplied by Sydney Water.

After more than three decades as an engineering and asset management professional, Tim McCarthy, Director at Morrison Low, says the most profound technological shifts for him have been in asset management systems and the availability of condition assessment data.

“What I mean by that is back in the 80s and 90s, we used to engage companies that specialised in that to do it,” he tells

inspire.“It was prohibitively expensive to do it internally. A lot of that stuff now can be done in-house by a council’s own staff. And the data collection methods, the processes, the systems and the tools are becoming a lot more efficient, a lot more available to councils to use.”

McCarthy points out that the IoT has introduced a lot of new types of data to management, ranging from route optimisation for scheduled works based on vehicle GPS, on to information on the use of mower blades and other pieces of equipment, to feedback on when such equipment should be inspected and replaced.

“Previously we used to go off [things like] meter readings off machines, which weren’t that accurate in terms of how often the machine was being used,” he says.

“Now we can make better decisions.”

Among the unprecedented amount of data available to public works professionals is GIS, which has opened up clever mobility applications.

This is helping field workers do their jobs and councils to cut waste. An example is GIS software company ESRI partnering with the NT’s Power and Water Corporation to develop a mobility app to save water. The Living Water Smart project allowed field staff and plumbers to record leaks in real time, on the spot, and add these to a database, replacing pen and paper and issues around possible double handling of information.

According to Power and Water, this helped repair 3000 leaks, save $2 million annually, and did away with the possible need to build a dam or other new water supply.

Ultimately, the key for asset managers, according to Verity, is to make sense of high volumes of complex data types coming into the organisation, and to make informed infrastructure investment decisions at the lowest life-cycle cost.

“By seamlessly harnessing all the inputs into the management system from a variety of sources, from automated real-time monitoring devices to non-invasive assessment technologies, for example, we can minimise costs, manual validation and automate failure mode analysis objectively to help us predict the timing of intervention,” he says.

“This helps us better plan maintenance and capital strategies and keep service provision at the optimum level.”

In their reasonably brief commercial history, drones have proven useful in numerous data gathering applications, including volumetric estimation for earthworks, construction surveys, pest detection, aerial photos, asset inspection and beyond.

Sometimes “seeing the forest for the trees” is difficult, notes McCarthy. Getting above all that, so to speak, and taking aerial photographs or other types of information can provide a better conceptual view.

“[Drones have] become real handy for data collection, where you can actually take a picture of, say, a beach or a park and count the number of users you have in a park at that particular point of time,” he tells inspire.

“Just to start to map out the usage of facilities, and particularly then start to monitor and work out what needs to happen to that asset in the future. Do we need to expand it? Do we need to change? What are we doing: all that sort of stuff.”

Four technologies making an impact

GISGIS (geographical information system) is a type of tool for analysing and presenting geographical data versus other kinds of data.

A survey of 900 American Public Works Association members ranked GIS as number one in the top five most important technologies for public works for 2018.

DronesDrones have emerged in recent years as an unbeatable way to obtain high-quality images, survey and map, take the danger out of inspecting certain assets such as communications towers and more. As the APWA Reporter recently put it: “Call it a drone, a UAV or a UAS, but it’s almost certain: If your public works department doesn’t already have one, it soon will.”

Building Information ModellingIt’s hard to see BIM becoming less important for the architectural, engineering and construction industries. Recently Goran Gelic and Alexander McLeod from McCullough Robertson Lawyers argued in IPWEA’s

intouch e-news for BIM adoption, which is climbing sharply, to be nationally mandated and standardised.

The Internet of ThingsPredictions vary, but Gartner believes there will be more than 20 billion connected IoT devices by 2020. Vast insights will be achieved and value created from the data produced by these things, which will include cars, HVAC systems, water meters and more.